Custom Cut Glass

We made it easy to order glass cut-to-size without leaving your home

Beautiful job! Incredibly happy with your prompt delivery and beautifully finished glass, will definitely be using your services again. 5-Stars!

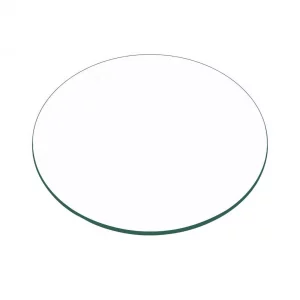

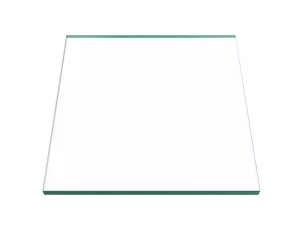

Step 1: Pick your Custom Cut Glass Shape

Step 2: Customize your Piece of Glass

Are you looking to order a large quantity of glass products? You can contact us at [email protected] or you can apply here to get contractor discounts.

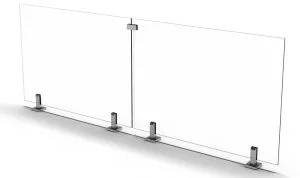

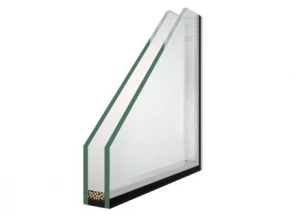

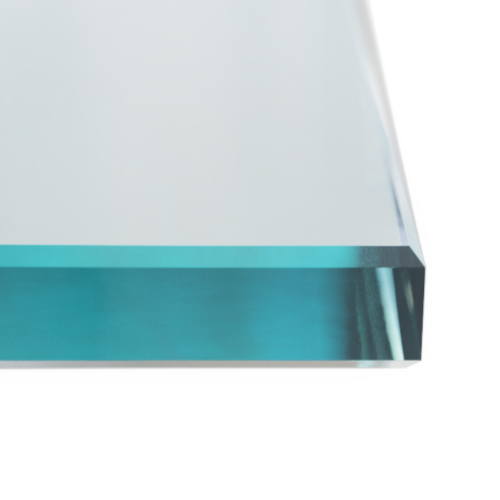

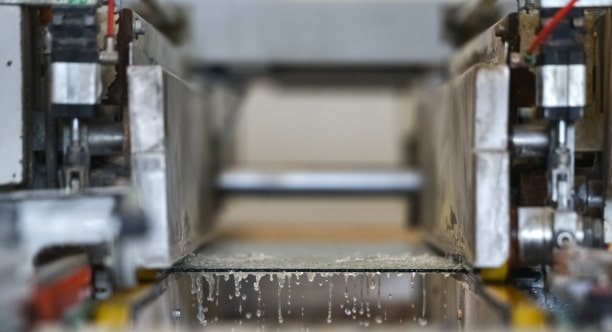

We make it our goal to offer high quality glass products that will exceed our customer expectations every time. We are a full service custom glass company, specializing in float (standard) glass, mirror, tempered glass, glass table tops, glass shelves, glass railings, glass showers & more. Traditional methods as well as modern CNC and Glass tempering furnaces equipment are used to fulfill small orders and large volume requirements. We have the ability to meet quick turnaround times with high quality glass products.Premium Glass Features

Projects – Uses of custom cut glass

FAQs about our custom cut glass products

Tempered or toughened glass is a type of safety glass processed by controlled thermal treatments to increase its strength as opposed to normal glass, which does not require this additional treatment. The manufacturing process places the outer surfaces under compression and the interior in a state of tension. Tempered glass is approximately four times stronger than “regular” or annealed glass. Also known as safety glass, tempered glass fractures into small, relatively harmless pieces. As a result, tempered glass is used in those environments where human safety is an issue. Tempered glass is commonly used for specific applications such as shower enclosures, glass tops, glass railings and so on. Our heat-treated tempered glass meets the current North American standards of ANSI Z97.1-04, ASTM C1048 and CAN/CGSB-12.1-M90, which are currently in place for safety glass.

Tempered glass cannot be cut, polished or drilled. All of the glass work must be performed prior to the tempering process.

1/32’’ Eased Corner Finish:

for safety purposes, the tip at each corner is slightly polished to remove sharp protrusions. This technique is known as the blunt edge. “Tips off” or “points off” are other terms used to describe this process.

The Radius Corner Finish:

This encompasses cutting the corners of the glass into a radius shape (round shape), which is then polished to give a smoother, safer finish. Corner radius describes how rounded the corners are on a rectangular glass cut. The term “corner radius” refers to the radius of the circle created by extending the corner arc to form a complete circle. Rounded corners are available up to a 4’’ radius.

The cutting tolerances in terms of industry standards for 1/8″, 3/16″ and 1/4″ thick glass is +/- 1/16″. The side shift is included for laminated glass. The tolerance levels for 3/8″ and 1/2″, +/- 1/8″, which also encompasses the side shift on our laminated glass.

Placing your order is quite simple and convenient. Simply select your preferred glass shape, insert the required dimensions, specify the thickness of your glass from the drop-down list, choose your glass type, ideal corner finishing and the type of edge work you require. Our list of frequently asked questions (FAQs) will also be helpful in choosing the product you desire in the ordering process. Our customized glass orders are then manufactured and packaged for delivery, to arrive at their destination in 7 to 10 business days.

The biggest glass we provide online is 119-5/16″ x 79 15/16″. Should you be interested in a larger piece of glass, our specialist glass professionals will be happy to provide you with a quote. Call us now on 1 (800) 897-2851 or you can request a quote online.